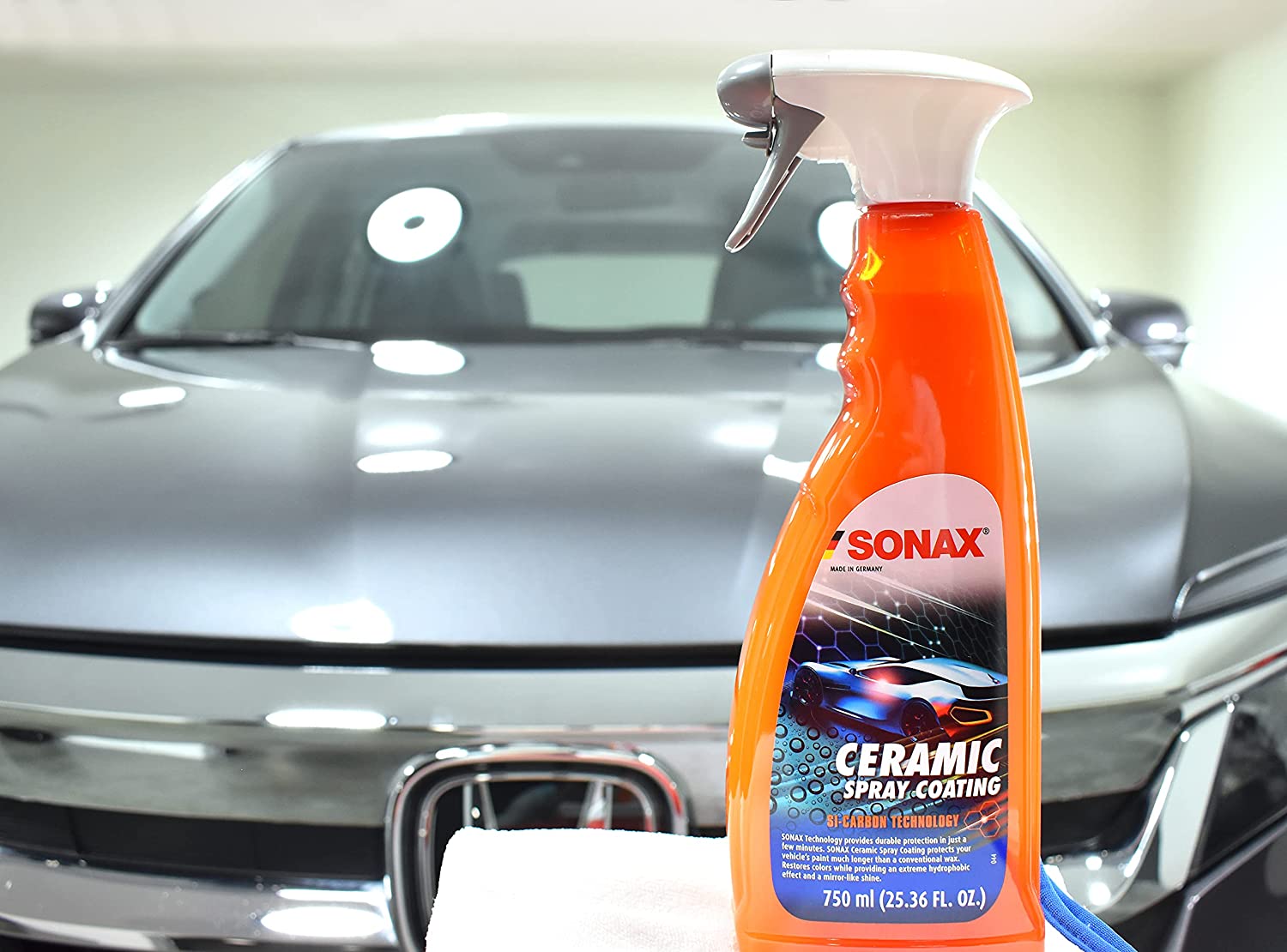

Ceramic Spray Coating: Improve Your Vehicle with State-of-the-Art Innovation

Ceramic Spray Coating: Improve Your Vehicle with State-of-the-Art Innovation

Blog Article

Achieving Specialist Results With Ceramic Spray Layer: Proven Approaches and Ideal Practices Revealed

As professionals in the field of auto describing and surface defense are frequently seeking methods to boost the top quality of their work, the application of ceramic spray finishings has become a game-changer. The allure of accomplishing a remarkable, long-lasting completed with very little initiative is undeniable. However, the path to understanding this method is paved with subtleties and intricacies that demand attention. Understanding the important tools, surface area preparation methods, specific application methods, and maintenance strategies are vital parts in the mission for professional-grade results. By uncovering the proven methods and best methods behind ceramic spray coating, a globe of possibilities opens up for those seeking to elevate their craft and provide impressive surfaces.

Benefits of Ceramic Spray Finishing

The advantages of utilizing ceramic spray finish in various applications are well-documented and commonly acknowledged in the commercial and automobile sectors. Ceramic spray finishes use outstanding protection against ecological impurities, UV rays, chemicals, and oxidation, supplying a sturdy guard for surfaces.

Additionally, ceramic spray finishes create a hydrophobic surface that repels water and protects against water spots, making cleaning and upkeep easier and much less taxing. The improved gloss and depth of color given by ceramic coverings can provide lorries and commercial equipment a showroom coating that lasts. Moreover, the scratch-resistant properties of ceramic finishings assist maintain the aesthetic appeal of surface areas in time, adding to the general worth and long life of the covered items. To conclude, the benefits of ceramic spray covering make it a preferred option for protecting and boosting surface areas in a variety of applications.

Essential Devices and Products

Having recognized the benefits of ceramic spray coating, it is imperative to detail the crucial tools and products needed for its efficient application in different markets. To accomplish professional outcomes, the following materials and devices are important:

Ceramic Spray Coating: The heart of the procedure, the ceramic spray covering itself provides the safety layer that improves longevity and aesthetics. - ceramic spray coating

Microfiber Towels: Used for wiping down the surface area before applying the ceramic spray finish and for rubbing off excess item after application.

Spray Bottles: Important for evenly distributing the ceramic coating onto the surface area.

Protective Gear: Gloves and masks to guarantee safety and security during the application procedure.

Sprucing up Compound: For preparing the surface by removing any kind of blemishes prior to applying the ceramic layer.

Clay Bar: Aids in decontaminating the surface area by removing ingrained bits, guaranteeing a smooth application.

Application Pads or Applicators: Made use of for uniformly spreading out the ceramic spray layer onto the surface.

Appropriate Surface Area Prep Work Techniques

Reliable surface area preparation is essential to guaranteeing the effective application of ceramic spray coating in different sectors. To accomplish ideal outcomes with ceramic spray layer, proper surface area prep work methods must be utilized.

The primary step in surface area prep work is comprehensive cleaning. ceramic spray coating. Any kind of dirt, wax, grease, or residue need to be entirely removed from the surface to make certain proper adhesion of the ceramic coating. This can be done utilizing a gentle cleaning agent or a committed surface area cleaner

Following, the surface area must be polished to remove any kind of imperfections such as swirl marks or scratches. This action not just boosts the look of the surface however likewise guarantees a smooth and even application of the ceramic finishing.

Application Tips for Optimal Results

To make certain remarkable outcomes with ceramic spray layer, thorough focus to application strategies is extremely important complying with the thorough surface area prep work treatments. When using ceramic spray finishing, it is vital to operate in a regulated setting without direct sunlight or solid winds. Optimum application problems usually consist of modest temperature levels and reduced humidity levels to facilitate appropriate healing and bonding of the finishing to the surface area.

Previous why not try this out to application, shake the ceramic spray coating container strongly to make sure the formula is well mixed. Begin by splashing a percentage onto a clean applicator pad or microfiber fabric to stay clear of oversaturation (ceramic spray coating). Making use of overlapping passes, apply the covering in a constant and also way to achieve uniform coverage. It is important to operate in tiny sections to assure extensive application and prevent the covering from drying out too soon.

After using the ceramic spray finish, enable enough time for it to cure according to the producer's guidelines. As soon as treated, make use of a high quality microfiber towel to delicately rub the surface area to a high gloss coating. By following these application tips diligently, you can achieve optimal results and maximize the protective advantages of ceramic spray layer.

Maintenance and Longevity Strategies

Sustaining the longevity and protective high qualities of ceramic spray layer calls for systematic and regular maintenance techniques. To ensure the finish remains efficient, routine cleaning with a pH-neutral vehicle shampoo is essential. This helps to remove dirt, gunk, and impurities that can degrade the covering over time. Furthermore, using a gentle microfiber clean mitt and drying out the automobile with a soft, tidy microfiber towel can protect against scratches and swirl marks that might endanger the covering.

Regular assessment of the coating is also essential for determining any areas that might require touch-ups or reapplication. This can be done by performing an easy water beading test or additional info aesthetically inspecting the surface area for any indicators of wear. Resolving any type of issues without delay can help preserve the finish's safety properties and extend its life expectancy.

Furthermore, staying clear of rough chemicals, abrasive cleaners, and automatic auto cleans can assist preserve the integrity of the ceramic spray finish. By why not try here complying with these upkeep methods, experts can guarantee their ceramic-coated automobiles preserve a high degree of defense and visual allure for an extended period.

Final Thought

To conclude, accomplishing specialist outcomes with ceramic spray coating needs mindful consideration of important tools and products, proper surface area preparation methods, and application tips for optimal results. By complying with tested approaches and best techniques, maintenance and long life of the coating can be maximized. It is essential to follow these standards in order to accomplish the wanted expert outcomes and ensure the efficiency of the ceramic spray coating.

As experts in the area of auto detailing and surface area security are continuously seeking methods to elevate the quality of their work, the application of ceramic spray finishings has actually emerged as a game-changer.Additionally, ceramic spray finishings develop a hydrophobic surface area that drives away water and stops water areas, making cleansing and maintenance simpler and much less taxing. In verdict, the advantages of ceramic spray coating make it a preferred option for shielding and boosting surface areas in a selection of applications.

To make certain exceptional results with ceramic spray coating, careful focus to application techniques is critical complying with the thorough surface area preparation treatments.In conclusion, achieving expert results with ceramic spray finishing needs cautious factor to consider of important devices and materials, proper surface area preparation strategies, and application pointers for ideal outcomes.

Report this page